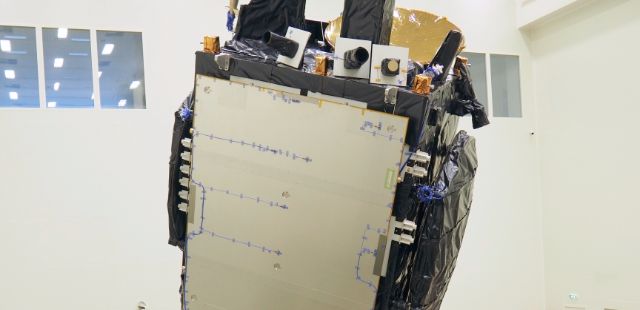

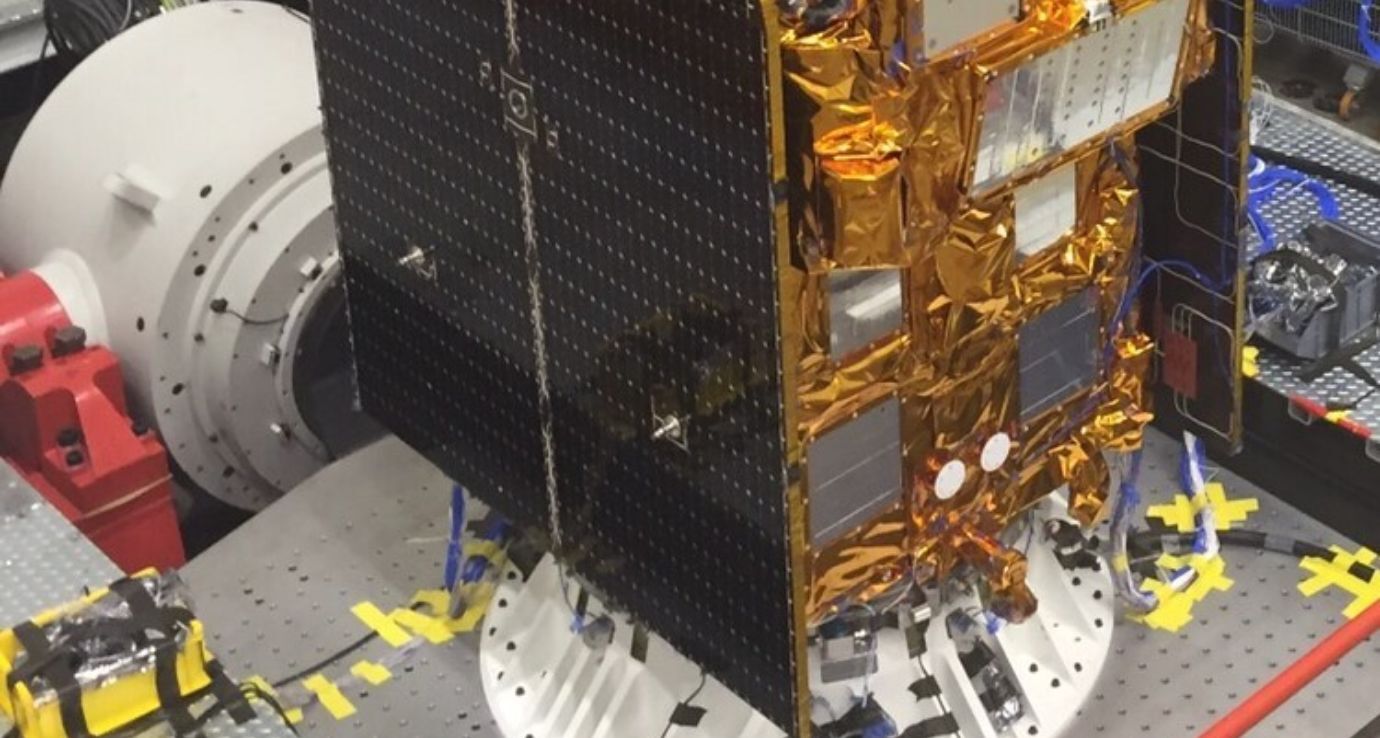

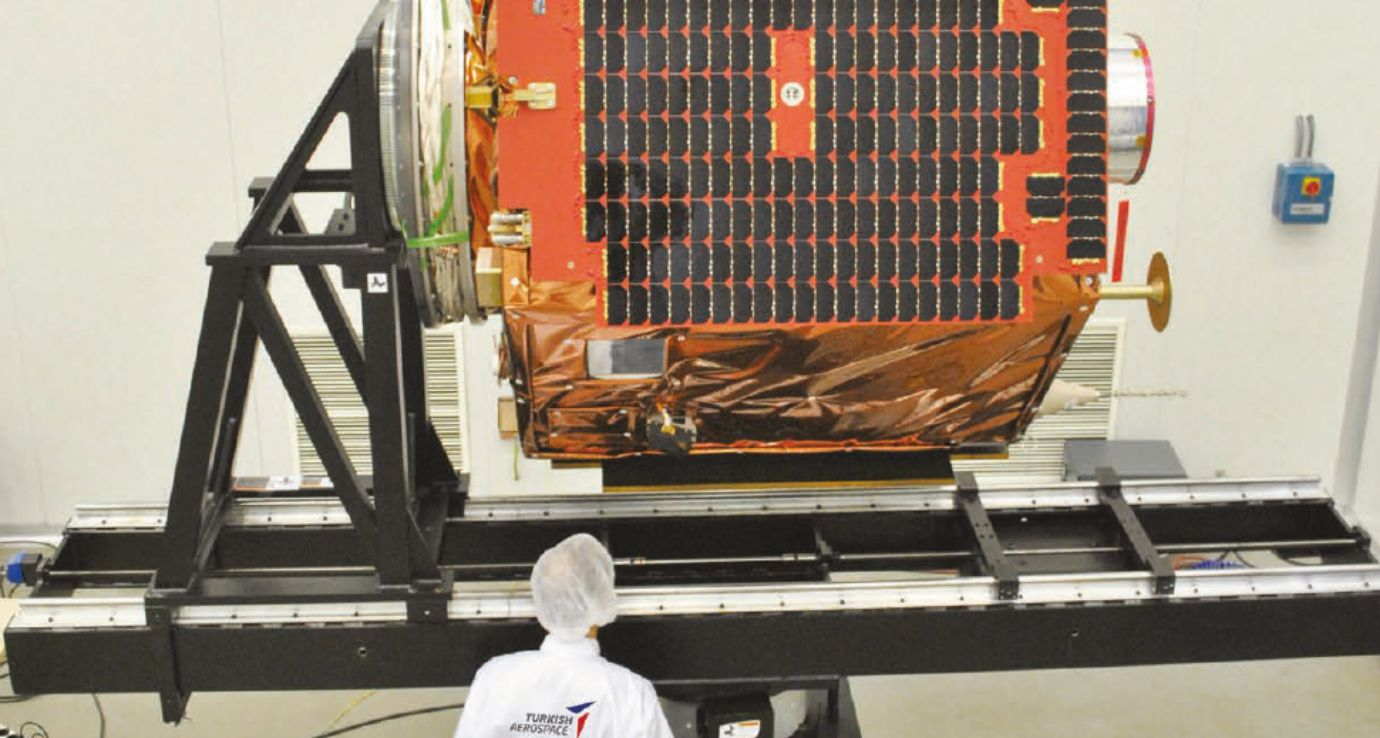

Turkey’s full grade state-of-the-art Space Systems Assembly Integration and Test (AIT) Center, which exist in a few developed countries leader in the space sector in the world is fully operational at Turkish Aerospace premises in Ankara.

AIT Center is designed to serve for assembly & integration activities, functional performance test and environmental test to be conducted all space systems for earth observation, communication and similar featured satellites until they are ready for launch activities. In addition, the facility has an infrastructure for manufacturing multi-layer insulation blanket, harness manufacturing and measurement processes and ground testing of space systems compatible with ECSS Standards.

This state-of-the-art AIT Center serves for more than one satellite up to 5 tons simultaneously by means of 3,800 m2 ISO-8 grade cleanroom and specific ground support equipment within the 10,000 m2 under roof approximately. Besides, ISO-6 grade mobile cleanroom offers high precision activities such as optical equipment/sensors, circuit board operation etc.

The time is crucial for system integrators and customers so, the direct connection of the AIT Center to the airport taxiway provides unique advantages in terms of safety, cost and risk management as well as opportunities to complete customs formalities within the premises.

Within the scope of satellite “Assembly” activities, it is aimed to form the main architecture of the satellite such as gathering primary and secondary structures including open end harness installation. By means of “Integration” activities, equipment and sub-system connections are performed to make satellite as functional. Assembly and Integration activities are followed by “Functional Performance Test” activities to generate all possible satellite mission scenarios. The purpose of the functional tests is to ensure that both satellite hardware and software is well functioning with respect to requirements/specifications based on the developed test scenarios related to the mission of satellite in space and performance verification of satellite components.

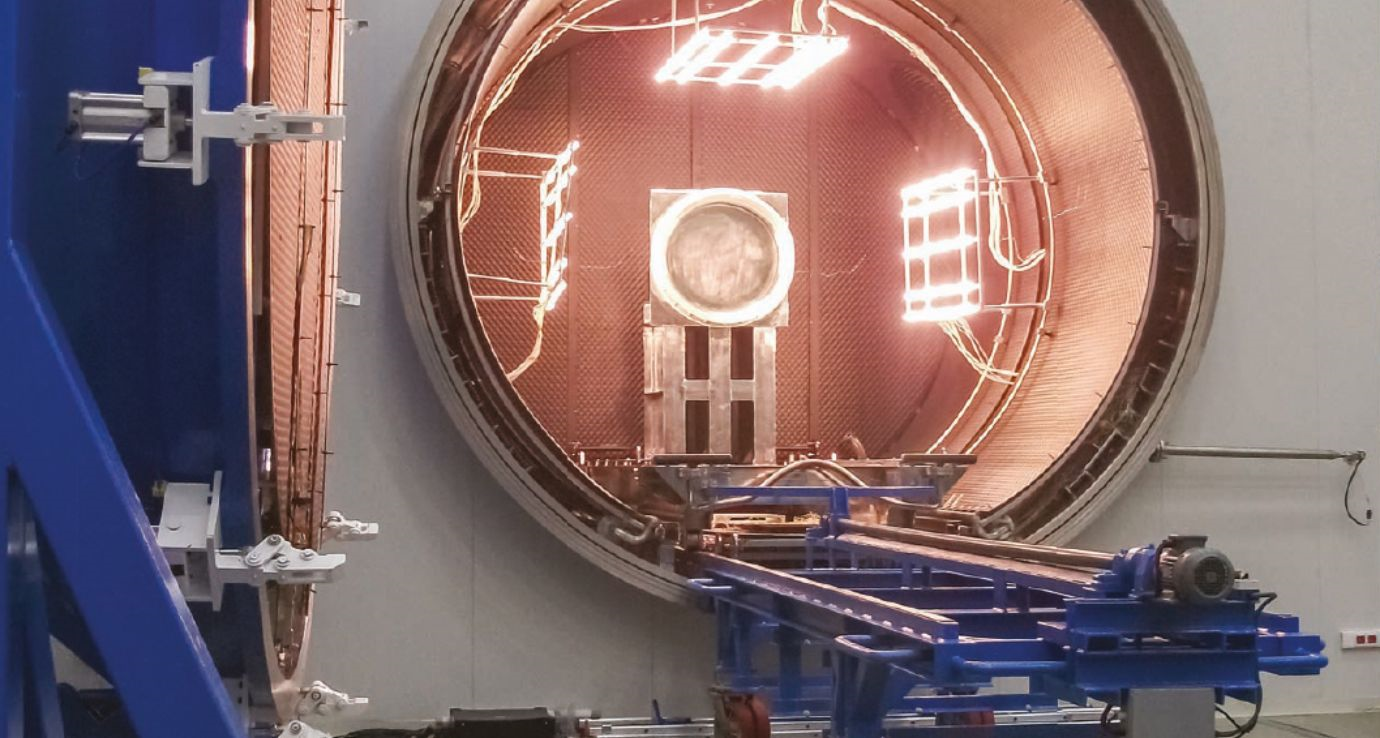

During "Environmental Testing", activities are performed to verify the qualification of satellite and its components against severe environmental conditions during launch and mission phases. The objective of these tests is to simulate environmental conditions from launch to space as close as real conditions and to ensure that satellite with its components exposed to these conditions are working properly. With these challenging activities, the requirements coming from the customers are also verified.

After all successful environmental and functional tests, the satellite will be ready for launch. Please click here for the Space Systems Integration and Test (AIT) Center test systems specifications.

Turkish Aerospace AIT Center aims to develop national space systems capability and provide benefits with space systems services to the international customers in the world. Our experiences and the versatility of state-of-the-art AIT facility privileged us in space systems activities against our competitors.

Turkish Aerospace continues for innovation in space systems by adopting emerging technologies and implementing new processes, products and solutions.

In addition to national projects, Turkish Aerospace Space Systems AIT Center offers transparent and comprehensive services to international distinguished customers.

This privilege enables Turkish Aerospace to submit competitive offers to its potential customers for their upcoming projects. Fully equipped Space Systems AIT Center that exists in a few developed countries in the world, makes Turkish Aerospace a challenging international player by providing assembly, integrations and test services for space systems.

Moreover, besides professional in-house engineering, analysis, manufacturing and test services, Turkish Aerospace ready to host its customers as an internal resident by means of guesthouse, shopping center, leisure centers, clinic, schools, kindergarden, etc. all inside the premises.